A paradigm shift for the construction industry

A green, high-quality, ultra-strong, water-, heat-, pest- and termite-resistant building material made from natural fibers and resins.

Renewable raw materials - the building material of the future

A paradigm shift for the construction industry with the innovative ![]() -panels from Smarter Habitat.

-panels from Smarter Habitat.

![]() is a green, high-quality, ultra-strong, water-, heat-, pest- and termite-resistant building material made from natural fibers and resins.

is a green, high-quality, ultra-strong, water-, heat-, pest- and termite-resistant building material made from natural fibers and resins.

From natural fiber to ![]() -panel

-panel

Natural fiber

Natural fiber fleece

Natural fiber laminate

Panel

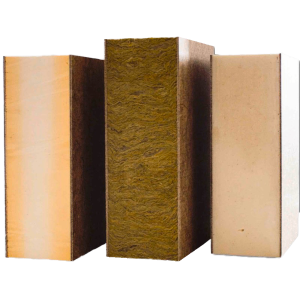

Panel variants

Popcorn as core material

Natural fibers

Green

Resins

High-quality

Ultra strong

Pest resistant

Termite resistant

Fire resistant

Heat resistant

Water resistant

The product – from the natural fiber to the

![]()

-panel

These panels are a green all-rounder – and a renewable raw material.

CO₂ neutral

- The world's only sustainable replacement for conventional building panels

- No use of sand, cement, water and only low energy use in production

- cradle-to-cradle Product

- Completely recyclable

Cost-effective

- Scalable by using known industrial manufacturing processes

- Consists exclusively of very readily available plant raw materials

- Developed and produced in Germany

Easy to install

- Reduces working time on the construction site by at least 50%

- The use of untrained assistants is possible

- Enables ergonomic work due to the low component weight

- No heavy machinery on the construction site

Highly resilient

- Carries heavy loads

- Excellent insulating properties with significant energy savings

- Durable and waterproof, algae and mold resistant

- Fire resistant according to the required standards

- Are vermin, hurricane and earthquake resistant

The panels are a green all-rounder

- Scalable by using known industrial manufacturing processes

- Consists exclusively of very readily available plant raw materials

- Developed and produced in Germany

Roadmap

Phase 1

PU-Foam

In the beginning there was the PU foam. Cheap and easy – but also not sustainable

Phase 2

Popcorn

The sandwich panels consist of two basic components: natural fiber laminates as a top layer and a core material made from popped corn granules. They can be manufactured in a wide variety of dimensions and thicknesses. Natural Composite Laminates (NCL) consist of natural materials such as hemp, flax, sisal and other long-fiber agricultural waste, which are processed into a fleece felt and pressed under high pressure with a special resin.

Phase 3

Social humanitarian enterprise

SMARTER HABITAT MISSION: “CREATE AFFORDABLE HOUSING FOR PEOPLE AROUND THE WORLD”

Phase 4

Franchising / License

Our goal is for construction companies and suppliers worldwide to use our panel as a standard material and so there will be “living space” for everyone.

Frequently Asked Questions

Questions and answers about the product.

Have we convinced you?

Invest now and take part in the paradigm shift in the construction industry.