Delivering a Better Future "Made in Germany"

A Global Social and Humanitarian Venture

SMARTER HABITAT’s mission to create affordable housing for millions of people around the world can be summarized as casually and simply. The triad of ecological, economic and social-humanitarian responsibility determines the roadmap of the Munich-based company founded in 2019. The goal: To create a building material from “green” bio-based materials and agricultural waste that can be produced regionally in large quantities cost-effectively and in an energy-saving manner and can also be installed quickly and easily. The product: – a plant-based and completely sustainable lightweight panel developed in cooperation with the Fraunhofer Institute IMWS and the University of Göttingen – meets all of these requirements. SMARTER HABITAT will license the know-how worldwide and thus help solve one of the most pressing problems on earth.

In the beginning there was “Awakening”

When Datty Ruth, CEO of SMARTER HABITAT, visited Haiti in 2012 two years after the devastating earthquake, the impression of the inhumane accommodation and the disastrous rubble field in which many people lost their lives drove him to the vision of giving people a decent roof over their lives head to enable. In view of the increasing number of trouble spots around the world – be it due to natural and climate disasters, poverty or wars and the resulting flows of refugees – but also the increasing need for housing, this vision became a mission. Back in 2013, he faced this major social and humanitarian challenge and decided to do everything he could to make affordable, safe and environmentally friendly accommodation available to everyone, everywhere. According to estimates by UN-Habitat and the World Bank, there is already a shortage of around 300 million houses for over two billion homeless people, and the number is expected to double by 2030 – not counting the estimated 80 million refugees worldwide.

– From the idea to the product

– From the idea to the product

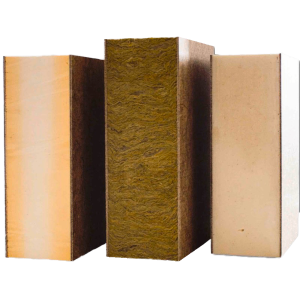

SMARTER HABITAT has now come a big step closer to this goal with its composite panels. After years of research and development and supported by a network of experts from science, technology and industry, a building material has been created that, as a “green” alternative, will not only revolutionize the construction industry in the future, but also accelerate the paradigm shift towards responsible sustainability in construction. The

sandwich panels consist of two basic components: natural fiber laminates as a top layer and a core material made of popped corn granules, which can be manufactured in a wide variety of versions. The Natural Composite Laminates (NCL) consist of natural materials such as hemp, flax, sisal or rice straw and other long-fiber agricultural waste, which are processed into fleece felt and pressed with special resin under high pressure.

From natural fiber to  -panel

-panel

Natural fiber

Natural fiber fleece

Natural fiber laminate

Panel

Panel variants

Popcorn as core material

In cooperation with the Fraunhofer Institute for Microstructure of Materials and Systems IMWS, a research facility of the Fraunhofer Society in Halle (Saale) and the C3 Technologies Gmbh, which is also based there, the material and process engineering fundamentals were established as part of several years of joint research and development work the industrial production of -laminates.

Since 2016, there has been a model house on the institute’s grounds that proves how sustainable, simple, cost-effective and unlimitedly scalable building can be in the future. By investing in C3 Technologies GmbH, SMARTER HABITAT secures this innovative knowledge for the transfer of the process from the laboratory scale to the industrial production of composite panels.

Material technology Made in Germany

At the same time, the “Chemistry and Process Engineering of Composites” working group at the Faculty of Forestry and Forest Ecology at the University of Göttingen, which has been researching renewable raw materials for years, has developed popcorn granules as a composite for laminates made from hemp and flax, which will be used in the future can replace PU foam previously used for panels. The head of the research group, Prof. Dr. Alireza Kharazipour – often referred to as the “popcorn professor” – sees this unique process as an outstanding opportunity to replace the raw material and energy-intensive products made of cement, gypsum or petroleum-based products previously used in the construction industry with a cost-efficient, almost 100% natural product. Prof. Kharazipour has obtained several patent rights in 14 years of research.

In addition to excellent physical properties, this building material is also reusable, recyclable and compostable and embodies a holistic sustainability claim like no other product thanks to the cradle-to-cradle principle.

SMARTER HABITAT has concluded a license agreement with the University of Göttingen, which secures the company worldwide commercial use rights for the patents for the distribution and production of the -panels.

A sustainable building material for global climate change

In ecological, economical and humanitarian terms, the innovative ![]() -panels have an outstanding record in terms of raw material, material and production efficiency, in contrast to previously conventional building materials.

-panels have an outstanding record in terms of raw material, material and production efficiency, in contrast to previously conventional building materials.

8 of the 17 UN goals have already been achieved

reduced energy use, as no use of sand, cement, steel, gypsum etc. with high energy and water intensive construction and heavy machinery,

environmentally friendly production from regional/local raw materials,

optimal heat and sound insulation properties,

Long-lasting, as it is waterproof, fire-resistant and mold and vermin resistant,

high load capacity and outstanding stability.

simple lightweight construction with faster and more efficient assembly (approx. a week for a 50m² house),

reduced assembly, transport, logistics and energy costs,

improved working conditions through reduced dirt and dust pollution,

suitable for all types of surface treatment,

consistently high quality and good scalability through industrial production.

Can be implemented quickly and easily globally through on-site production,

cost-effective through the use of regionally and locally available raw materials,

Creation of jobs in the construction sector and the possibility of employing unskilled workers,

Significant overall improvement in the living conditions of people at risk of housing shortages.

non-load-bearing applications such as partitions or dry walls,

decorative applications such as building cladding, kitchen or sanitary

Elements,

Further applications: trade fair and shop fitting, mobile homes and tiny houses

Ship interior design and much more

In total, the -panels provide eight out of 17 of the United

Nations set sustainability goals. They have the potential to fundamentally change construction in the future and thus alleviate the global housing crisis.

The need for affordable housing is huge – in both developing and developed countries. UN Habitat estimates that around 3 billion people will be without adequate housing by 2050, representing a $424 billion market. Governments and NGOs worldwide are allocating enormous budgets to reduce these shortages.

A value-based business model for rapid global market development

The prerequisite for this is the expansion of two business areas:

SMARTER HABITAT pilot factory

SMARTER HABITAT license (franchise concept)

Own code of ethics and corporate governance

Own code of ethics and corporate governance

Invest in a good cause

Given the increasing number of climate catastrophes in recent years, which have caused massive damage in many regions of the world, it is high time for a general rethink. As early as 2020, the World Economic Forum listed the risks triggered by climate change in its Global Risk Report as one of the top five and sees ESG risks (E = Environmental, S = Social, G = Governance) in particular the greatest dangers with enormous social and economic consequences.

Therefore, the motivation to make a positive contribution to a sustainable future for the environment and society should be great. All the more so because an investment in environmentally friendly, CO₂-neutral technologies is not only reflected in returns, but – as SMARTER HABITAT’s business model shows – can also fundamentally improve the living conditions of millions and billions of people.

So that it can now move from the project planning phase into implementation, the company is raising capital for its investments. The options for impact investors are direct investments as limited partners or via subordinated loans. Detailed financial plans and conditions can be requested. In addition, small investors and socially and humanitarian-oriented people have the opportunity to get involved through crowdfunding approved by BAFIN. Everyone who wants to take part in the good cause and who values a sustainable but also promising and promising investment is invited – private individuals as well as institutional investors or private equity and venture capital investment companies.

Our management introduces itself

The advisory team

SMARTER HABITAT’s management team is also supported by a number of internationally renowned consultants who bring their respective expertise to the company:

The Hemmelrath Compagnie under the direction of Prof. Dr. Alexander Hemmelrath combines tax, legal and business advice for SMARTER HABITAT into a holistic range of services. The business consulting that is currently the focus is carried out under the leadership of Konstantin Hemmelrath.

Benedikt Hoffmann, Advisor on International Finance/Board Member, has decades of experience as a bank manager, particularly with a regional focus on international growth markets. He has led banks in various emerging markets and cultural environments. As an expert in a wide range of international regulatory and accounting standards, he will contribute his knowledge in connection with international financing.

Dr. Ndidi Nnoli-Edozien, Advisor on Corporate Sustainability and Governance/Board Member, is an expert in social entrepreneurship and sustainability. She established the Seven Pillars of Sustainability, based on 20 years of research, in Africa’s largest company. She will advise SMARTER HABITAT on sustainability, corporate governance and international company development. Dr Nnoli-Edozien is a member of the Club of Rome.

Dipl. Ing. Anabela Macieira, Advisor Engineering and Construction, is an international award-winning architect, owner of Core Architects – one of the few “Passive House” and NETZEB-certified architectural firms in Portugal. She designs nature-inspired, sustainably chic buildings that support the holistic health of residents. In the government approved projects that are the latest

Even exceeding sustainability standards, the innovative building material from SMARTER HABITAT is used.

Peter Schalburg, MBA, Advisor Licensing, has led international franchises for most of his career. He has many years of international experience in all major markets, including 15 years as President and CEO of Midas Europe and South America with more than 600 franchisees/license partners.

Our partners